Press Release

MAPP Technologies, L.L.C. Receives EASA Part-145 Certificate

Joplin, MO, Release: January 18, 2023. For Immediate Release.

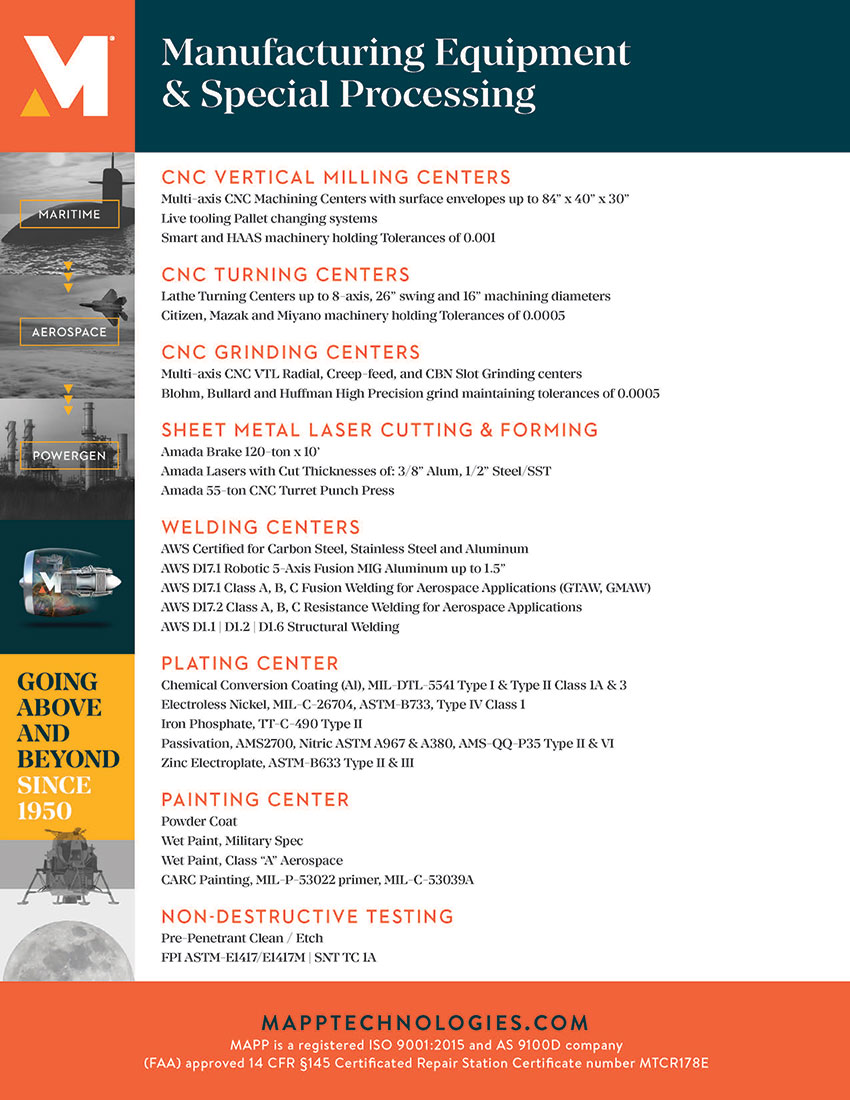

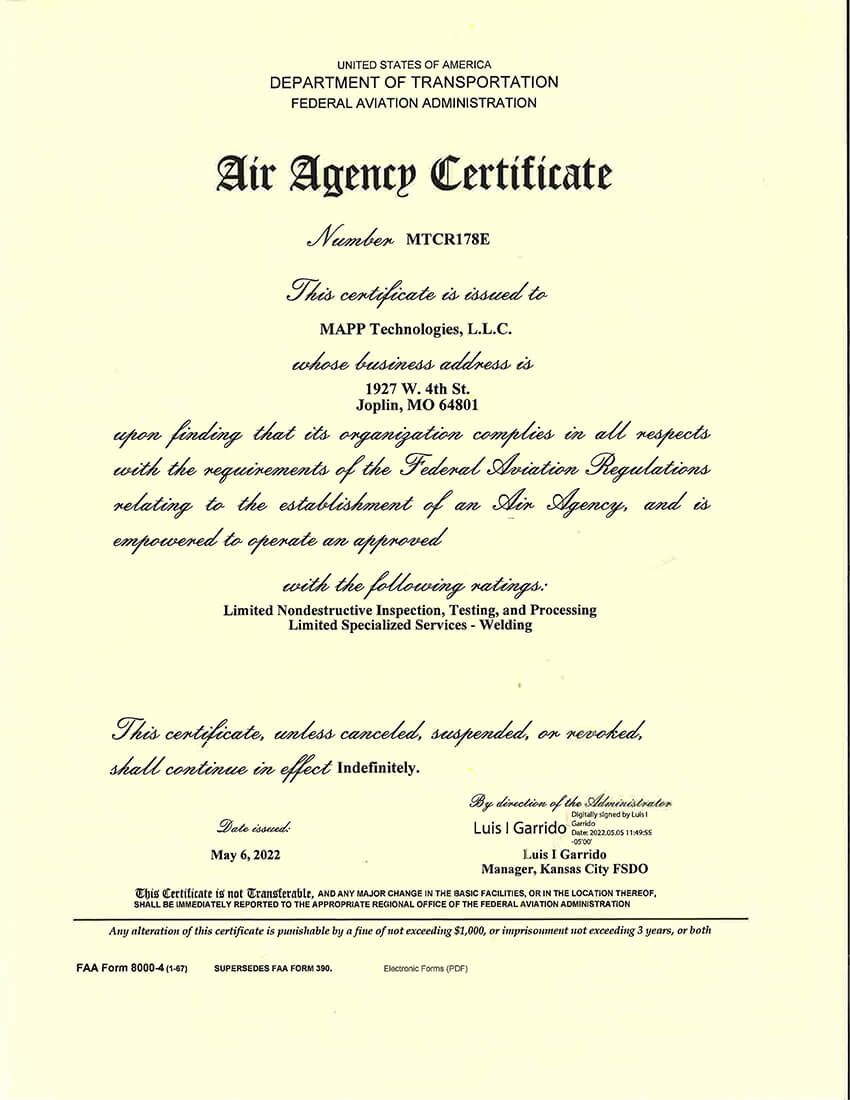

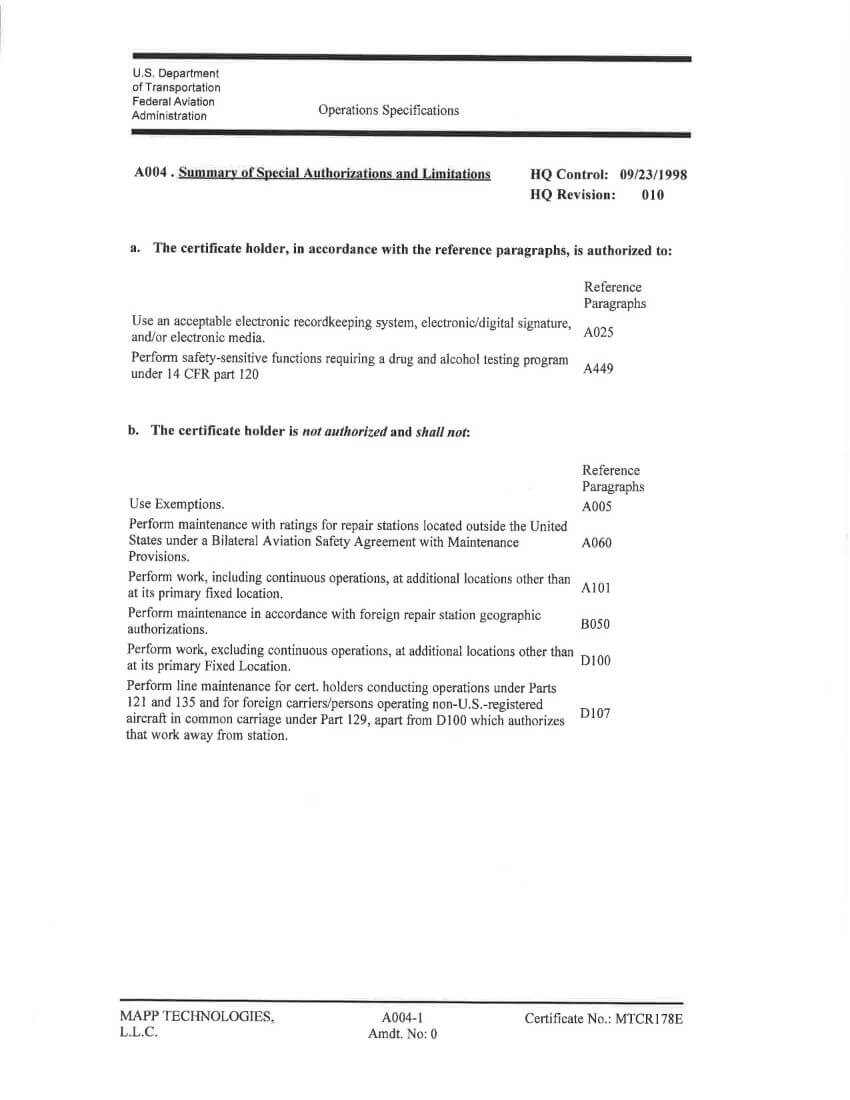

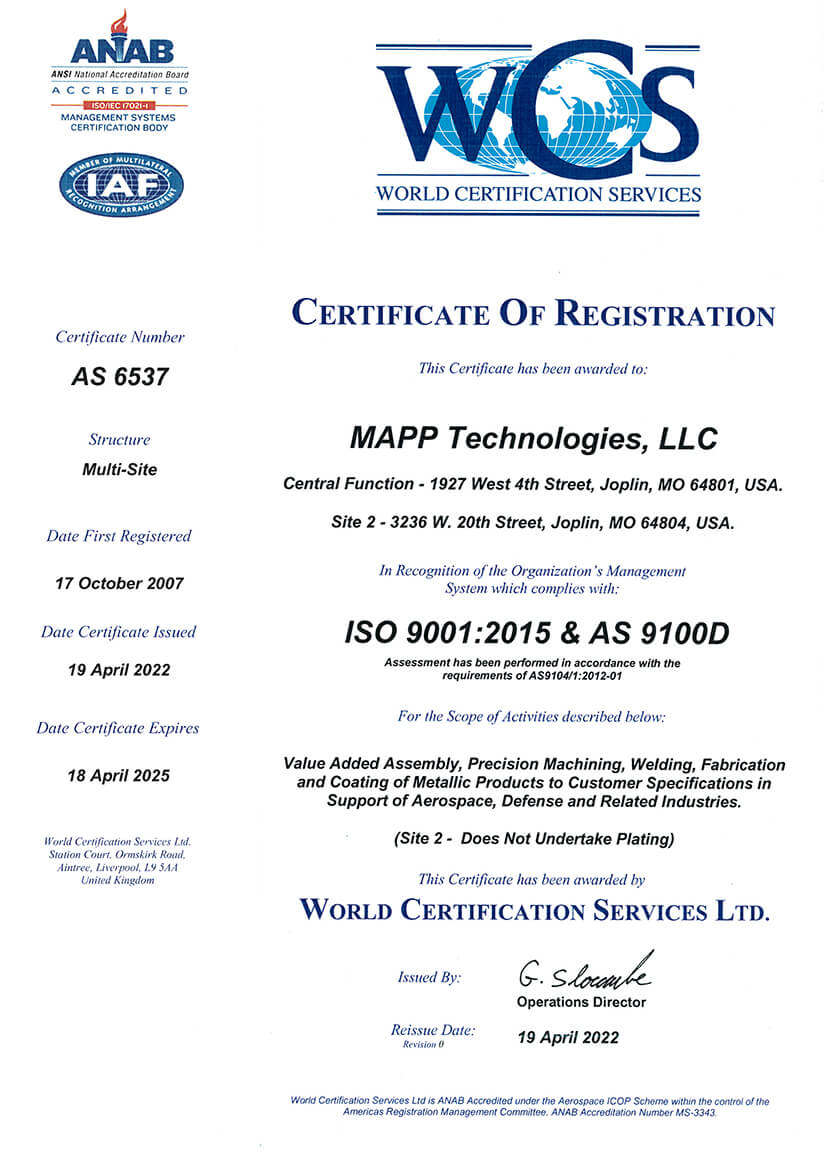

MAPP Technologies receives Initial issue of EASA Part-145 approval in accordance with the provisions of the Agreement between the United States of America and the European Community on Cooperation in the Regulation of Civil Aviation Safety. Having dual-release authorization allows MAPP to better support our global MRO customers.

Maintenance, Repair and Overhaul (MRO) operations specializing in Clean & Inspect, Weld Repair, NDT, Dimensional and Final Inspection applications. Located on the same campus as our OEM business, the Joplin, MO aftermarket repair operation maintains a unique position, leveraging synergies between the two business segments to offer operational excellence to a diverse portfolio of global OEM and MRO customers. We take pride in being best in-class at machining, welding, special processes, and customer service.

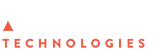

Primary in-house MRO capabilities include:

Inspection

Aqueous Clean

AMS D17.1 TIG welding

FPI Non-Destructive Testing

CMM dimensional Inspection

8130-3 Return to Service

CEO Luis Coreano said, “It’s a great day for MAPP Technologies as we better serve our European customers by expanding our MRO offerings to include EASA certification. Delighting our customers through exceptional service and product support is what MAPP is all about.”

About MAPP Technologies

Joplin, Missouri based MAPP Technologies L.L.C. is a privately-held manufacturing and aftermarket services company delivering critical components to OEM specifications using specialized process capabilities; from raw material through complex machining, welding, coating, assembly, and final inspection – Providing best-in-class value, quality, and just-in-time delivery to our global customers throughout the maritime, aerospace, and power generation industries. We contribute to a world in which people reliably feel protected, safe, and secure.